SUPPORT

EARNEST · RIGOROUS

DEDICATED · PROFESSIONAL

Common Valve Knowledge

Release time:

2024-10-06 11:38

Source:

Commonly Used Connection Method

- Commonly Used China National Flange Standards: Ministry of Machine-Building Industry JB/T79-1994, China National Standard GB/T9124, Ministry of Chemical Industry HG/T20592, Ministry of Chemical Industry (American System) HG/T20615, generally default JB/T79-1994 Commonly Used Foreign Flange Standards: ASME Standard, ASTM Standard, ANSI Standard, JIS Standard, DIN Standard, BS Standard

- Commonly used thread: Metric Thread---e.g. M20×1.5, which is cylindrical thread; British Standard Pipe Thread---e.g. G1", Rp1", PF1", which is 55° pipe thread without pressure-tight joints;British Standard Taper Pipe Thread---e.g. PT1/2"=ZG1/2"=R (Rc)1/2",which is 55° taper pipe thread with pressure-tight joints (whitworth thread), the internal thread presented as Rc,external thread pres-ented as R; American standard thread ---1/2" NPT which is 60° taper pipe thread.Taper pipe thread has function of self-sealing.

- Common dimension conversion: 1"=25.4mm=8 copies 1 copies=1/8"=3.2mm ··· 4 copies=1/2"=12.7mm ···

Commonly Used Pressure Unit Conversion

1kgf/cm2 =1bar=0.1MPa=100KPa=105Pa=14.5PSI (Lbf/in2)=10m Water Column=1 (Engineering) Normal Atmosphere=10m Lift

Conversion among ANSI, GB and JIS Metric Pressure Unit

Commonly Used Sealing Material

1.Nitrile Rubber (NBR)

Most commonly used sealing material, mainly used as seal, diaphragm, O ring, etc. Applicable medium temp.-9~80℃,theoretical max.

temp. tolerance 120℃, brittle temp. -10~-20℃.

2.Ethylene Propylene Diene Terpolymer (EPDM)

Mainly used for gas, liquids, applicable medium temp. -39~140℃, theoretical temp.-resistance is 150℃,brittle temp.-40~-60℃. It's

the best sealing material for acetone. Good Ozone-resistance, but not suitable for oil.Applicable for food-grade medium.

3.Fluororubber (VITON, FKM or FPM)

Mainly used for the sites not suitable for NBR, EPDM, ideal sealing material for strong corrosive medium (e.g. Hydrogen Nitrate, Sul-

furic Acid, etc.) and low temp. vapor. Applicable temp. is -9~180℃, theoretical temp. tolerance is up to 200℃, brittle temp. -10~-50℃.

Not suitable for acetone alike medium. It's poisonous and not suitable for food-grade medium.

4.Fluoroplastic (PTFE)

Fluoro plastic is called as Teflon or polytetrafluoroethylene, very excellent heat-resistant and cold-resistant feature, applicable medi-

um temp. is -268~232℃, brittleness is not obvious under low temp., but due to its hardness, used for normal&low temp. medium, leak-

age might happen under low pressure, ideally used temp. is 120~220℃, and often used as the sealing material for vapor. Under high te-

mp., it will soften and show a very satisfactory sealing performance. Applicable for food-grade medium.

5.Silicone Rubber

The heat-resistant characteristic of silicone rubber is very outstanding, which can be used between -69~200℃, theoretical heat-resist-

ant tolerance is 315℃, brittle temp. -70~-120℃, strong chemical inertness, normally used as seal and diaphragm material for hot wat-

er, but with weak mechanical strength and expanding easily, the working pressure is only 1/3 of NBR´s. Food grade medium optional.

6.Copper (Cu)

When medium temp. is among 250~450℃, copper is adopted as sealing material. After being softened under high temp., the leakage is

almost zero or on a very low level. Copper is usually used as sealing material after anneal under high temp. It's an ideal sealing material

for overheated vapor&overheated transfer oil. The temp. lower bound is -273℃.

Commonly Used Unit Conversion

1. Temp. ℃=5/9 (℉-32) ℃---Celsius (Metric) ℉---Fahrenheit (British)

2. Volume 1L=10-3m3=1000ml 1ml=1 cm3 L---liter ml---milliliter m3---cubic meter cm3---cubic centimeter

3. Flow 1L/h=10-3/3600 m3/s L/h---liter/hour m3/s---cubic meter/second

4. Kinematic Viscosity 1CSt=1mm2/s CSt---Centistoke (formerly called centisthene)

5. Others 1foot=12 inches 1Lb·foot=0.11N·m

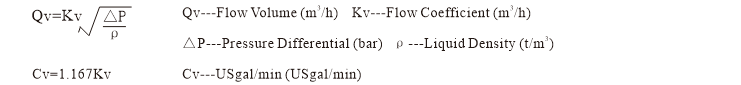

Flow Calculation of Commonly Used Fluid

Density&Viscosity of Common Medium and PH Value of Aqueous Solution

- Density of 20℃ 1 (Engineering) Normal Atmosphere water=1000kg/m³, relative density=1, kinematic viscosity=1CSt

- Density of 20℃ 1 (Engineering) Normal Atmosphere air=1.293kg/m³, kinematic viscosity=15CSt

- Density of 20℃ 1 (Engineering) Normal Atmosphere ordinary oil=850kg/m³, relative density=0.85, kinematic viscosity=22CSt

- Generally PH=6.5~8.0---neutral aqueous solution; PH=5.0~6.4---weak acid; PH<5.0---strong acid; PH=8.1~10---weak alkali. PH>10---strong alkali, PH=7---neutral; The smaller the PH value, the stronger the acidity; the bigger the PH value, the stronger the alkalinity

Size of Commonly Used British Thread

Temp./Pressure/Density of Common Saturated Vapor

Data below is not suitable for overheated vapor

Unit Conversion Table for Commonly Used Meshes

Stainless Steel Commonly Used Domestically and Internationally

SS304=CF8=0Cr18Ni9[0Cr19Ni9]=X5CrNi189 SS316=CF8M=0Cr17Ni12Mo2 [0Cr18Ni12Mo2Ti]=X5CrNiMo1810

SS304L=CF3=00Cr19Ni10[00Cr18Ni10]=X2CrNi189 SS316L=CF3M=00Cr17Ni14Mo2=X2CrNiMo1810

SS321=1Cr18Ni9Ti[0Cr18Ni9Ti]=X10CrNi189 SS410=1Cr13=X10Cr13 SS420J1=2Cr13=X20Cr13

Common Protection Grade

01. IP54---5 stands for dust-proof (when little dust enters, no downtime), 4 stands for splashing-proof (little water splash, no negative effect).

02. IP65---6 stands for dust tight (no dust enters), 5 stands for spraying-proof (no negative effect from water spraying of any direction).

03. IP56---5 stands for dust-proof (when little dust enters, no downtime), 6 stands for sea wave-proof (no negative effect under strong water

spraying).

04. IP67---6 stands for dust tight (no dust enters), 7 stands for immersing-proof (when immersed in water for at least 30 min, no negative

effect), applicable for outdoor use.

05. IP68---6 stands for dust tight (no dust enters), 8 stands for underwater working (working underwater within the pressure specified, no

negative effect).

Common Explosion-proof Marks

01. Flameproof---Ex-marks: ExdⅡBT1~T4, ExdⅡCT1~T5

【Some medium and large diameter solenoid valves of BEST Company use flameproof protection】

02. Encapsulation---Ex-marks: ExmbⅡCT4

【Some medium and small diameter solenoid valves of BEST Company use encapsulation protection】

03. Intrinsic safety---Ex-marks: ExiaⅡCT6, ExiaⅡBT6

【Positioners of all pneumatic control valves can use intrinsic safety protection】

04. Increased safety---Ex-marks: ExeⅡCT5

【At present, BEST's products have not adopted this explosion-proof protection yet】

Terminology of Valve

01. Nominal Pressure: It’s the maximum allowable pressure under normal temperature, offered by user (customer) based on the pipe or system

parameter, represented as PN.

02. Working Pressure: The pressure that when medium flows through the valve, also called medium pressure.

03. Max. Working Pressure: Under specified temperature, the max pressure that the valve can work properly.

04. Max. Pressure Differential Tolerance: When valve works normally, the allowable pressure differential between inlet and outlet.

05. Applicable Pressure: When valve works normally, the allowable range of the working pressure.

06. Nominal Diameter: It's the uniform pipe/valve size, represented as DN, used in all the related pipe accessories.

07. Applicable Temp.: When valve works normally, the allowed range of medium temperature.

08. Applicable Ambient Temp. : When valve works normally, the allowed range of ambient temperature.

09. Shell Test Pressure: Also shell hardness test, generally, Ps=1.5PN (GB/T13927, ISO5208).

10. Sealing Test Pressure: Check open/closed parts, sealing performance, generally, Ps=1.1PN (GB/T13927, ISO5208).

Terminology of Safety Valve

11. Opening Pressure: Also named as setting pressure, defined as the inlet pressure when valve disc of safety valve is lifting up, at this point,

by visual check or hearing to judge the continuous discharge status of medium, the opening pressure=1.05~1.1 times the max working

pressure,which shall be determined after strict calculation.

12. Discharge Pressure: Inlet pressure when valve disc reaching specified open degree, the upper limit should be in compliance with national

standards or specifications. Vapor discharge pressure≤1.03 times opening pressure, gas discharge pressure≤1.1 times opening pressure,

liquid discharge pressure≤1.2 times of opening pressure.

13. Overpressure: Difference between discharge pressure and opening pressure. Usually represented as percentage of opening pressure.

14. Reseating Pressure: The inlet pressure of valve disc returning after discharge, at this moment, the open degree is zero, reseating pressure=

0.85~0.9 times opening pressure.

15. Engaging Pressure: The difference between opening pressure and reseating pressure.

16. Back Pressure: Negative pressure of safety valve's outlet (when the back pressure≥10% of the set pressure, bellows safety valve should be

used).

17. Chatter: Valve disc moves back and forth quickly and abnormally, touches the valve seat during the movement.

18. Flutter: Valve disc moves back and forth quickly and abnormally, doesn't touch the valve seat during movement.

19. Rating Discharge Pressure: Upper limit value of standard discharge pressure.

20. Sealing Test Pressure: The inlet pressure of sealing test, under such pressure, test the leakage of sealing material or parts. When the setting

pressure is≤0.3MPa, sealing test pressure=setting pressure -0.03MPa, when setting pressure>0.3MPa, sealing test pressure=90% of the

setting pressure.

21. Value Lift: The real lift height of valve disc lifting from the seat.

22. Flow Passage Area: The minimum flow passage area of valve disc's inlet end to closing part sealing surface, calculating theoretical

discharge without any resistance.

23. Flow Passage Diameter: The diameter of flow area, also called throat diameter, represented as d∅.

24. Curtain Area: When the valve disc is above the seat, the area of cylindrical or conical surface passage formed by its sealing surface.

25. Discharge Area: The minimum area of flow passage when discharging; for full lift safety valve, discharge area=flow passage area; for low lift

safety valve, discharge area=curtain area.

26. The oretical Discharge Capacity: The calculated discharge capacity of an ideal nozzle whose theoretical cross-sectional area of the

flow passage is equal to that of the safety valve.

27. Discharge Coefficient: The ratio of real discharge and theoretical discharge capacity.

28. Rating Discharge Coefficient: The result of discharge coefficient multiplying reducing coefficient [take 0.9].

29. Rating Discharge Capacity: It’s part of the real discharge capacity that can be used as applicable standard.

30. Equivalent Calculated Capacity: It’s the calculated discharge capacity of safety valve when the conditions such as temp., pressure, medium

property,etc. are the same as applicable conditions for rating discharge capacity.

SHANGHAI BEST AUTOMATION TECHNOLOGY Co.,Ltd.

HQ Add: No.3131, Jinshajiang Road, Jiading District, Shanghai, China

Domestic Sales Center: 8th Floor, Oriental Auto Parts City 3rd New Office Building, No.35, Dingbian Road, Jiading District, Shanghai, China

Phone: 021-57654321, 52751111

Zip Code: 201824

Foreign Trade Dept.: Room 813, 8th Floor, Oriental Auto Parts City 3rd New Office Building, No.35, Dingbian Road, Jiading District, Shanghai, China

Foreign Trade Hotline: 0086-21-66123456, 0086-21-66554433

Foreign Trade QQ: 2880686090, 2880686094, 2880686098

WeChat: 0086-18801801398, 0086-18801801318, 0086-18801801308

WhatsApp: 0086-18801801398, 0086-18801801318, 0086-18801801308

EARNEST · RIGOROUS · DEDICATED · PROFESSIONAL

Ten Production Capacity in China, Stable Quality

Ten Honesty Enterprises judged by government of Shanghai in China

mail link ma2

Pollyannasale01@bestautovalve.com

Pollyannasale02@bestautovalve.com

Viviansale03@bestautovalve.com

Victorsale07@bestautovalve.com

Copyright© 2024 Shanghai Best Automation Technology Co., Ltd. All Rights Reserved Website:66123456.com | bestautovalve.com | SEO Business License

Pollyanna

Pollyanna Vivian

Vivian